The Silverson Apprenticeship Scheme

The ProgrammeOur award winning training scheme was set up in 2014, moving into a dedicated new facility in September 2015.

We offer excellent rates of pay, first-class training and the opportunity for the successful candidates to enjoy a secure job with a modern, progressive company. It's a five year Apprenticeship, which offers the option to study for a Diploma in Advanced Manufacturing, Levels 2 & 3 as you progress through the scheme. The programme is structured but allows our Apprentices to specialise in a certain field if they show a particular skill or interest - ultimately providing us with a highly qualified, skilled and flexible workforce. Here's what you can expect: |

First Year Trainees

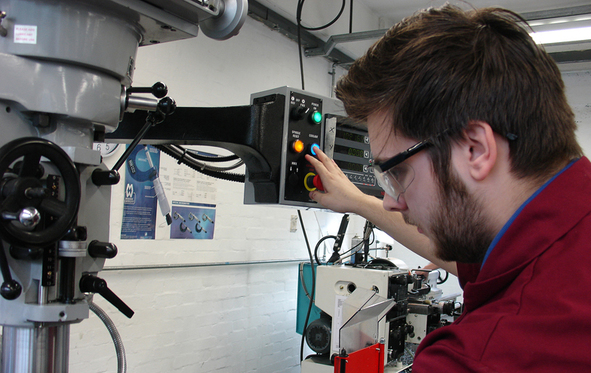

The first year as a Trainee is workshop-based in our dedicated Training Facility. Instruction in good working practice and Health & Safety is followed by training in practical skills.

You'll start with bench work, and progress to milling and manual turning. Regular appraisals will ensure you're hitting learning targets. |

|

A Day in the Life of a Silverson Apprentice - Year 2

|

Second Year and Beyond...

Trainees that pass the first year become Apprentices and go out into the big wide world - better known as the main shop floor.

Here you'll spend time on rotation in different departments on the shop floor, including Milling & Turning, the Fitting Shop (Assembly), Welding, Inspection, and Spark Erosion. While remaining under the overall guidance of the Apprentice Trainer, you will be working with an assigned mentor on a day-to-day basis. You'll soon find yourself part of a friendly team, and as you get a salary increase each year you'll be enjoying the benefits of working for a world-leading manufacturing company. |

Qualification

|

As you progress through the scheme, there's the opportunity to study for a Diploma in Advanced Manufacturing, Levels 2 & 3. While the majority of the study is done in your own time we provide onsite study sessions with tutors as well as the support of our Apprentice Trainer, to help you through the coursework.

|

Completion of the Apprenticeship

|

At the end of Year 5 you complete your Apprenticeship. You're now fully skilled and can work in most sections of our factory. If you've shown an interest or particular skill in one area you might remain there; some people prefer variety and like to move around - and this helps us manage work coming through the factory. Whichever course you take, Silverson provides a well-paid , secure job for the right candidates.

|

Entry Requirements

Ideally you'll have GCSEs in English, Maths and Science/Technology at grade 5 or above, but we do an assessment of your mechanical aptitude, literacy and numeracy at the interview stage, so if we think you've got what it takes we're prepared to be flexible.

|

Testimonials

Here's what some of our current and former Apprentices have to say about working here...

“You get to do a lot of different things - milling, turning, assembly, and gain broad skills that you need to be successful.” Luke - Year 4 Apprentice

“I'm learning a skill but earning a proper wage at the same time.” Richard - Lab Section Fitter

“The programme is well structured, but there’s no set pathway - some of us are into the assembly side, but I really like working on the lathes so I’m hoping to progress into that area” Ross - Year 4 Apprentice

“You get to do a lot of different things - milling, turning, assembly, and gain broad skills that you need to be successful.” Luke - Year 4 Apprentice

“I'm learning a skill but earning a proper wage at the same time.” Richard - Lab Section Fitter

“The programme is well structured, but there’s no set pathway - some of us are into the assembly side, but I really like working on the lathes so I’m hoping to progress into that area” Ross - Year 4 Apprentice

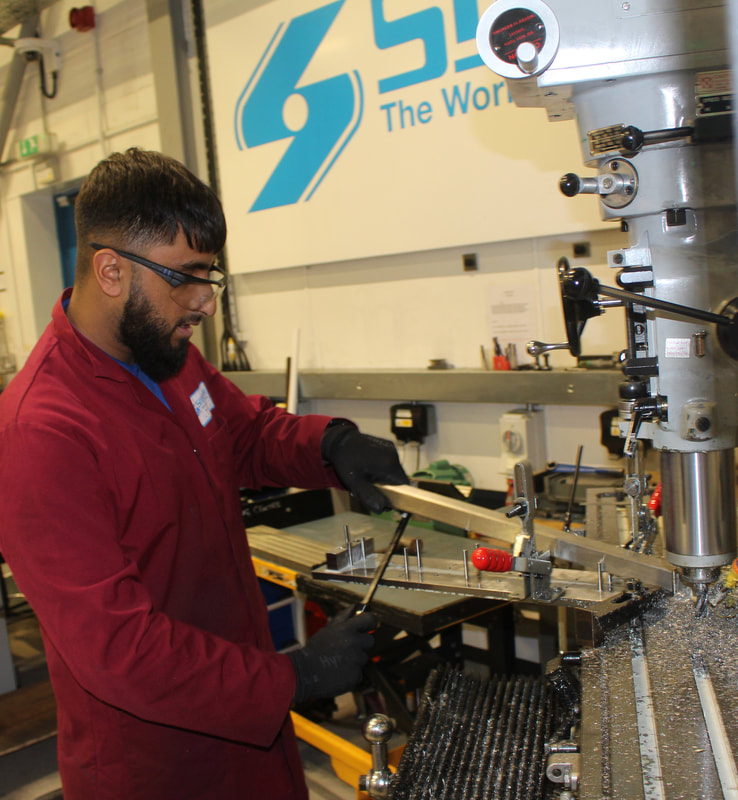

Muhamed, Year 1 Trainee

I always wanted to be an engineer, and I did Engineering at school and at college. It was mostly written work, so I decided to go for an apprenticeship as I wanted to do something more practical and more useful.

At Silverson it's much more hands on. I've learned more here in three months than I did at college - we only had a few hours a week on machines at college, but here we're working on a lathe or milling all day. |

|

Holly, Year 4 Apprentice

|

When I was at school I was interested in working in Accountancy and I went to Silverson to do work experience in the Accounts Department. While I was there I heard about Skills Week so I applied to do that. I enjoyed it so much I decided I wanted a career in Engineering.

I'm now in my fourth year in the Silverson Apprenticeship Scheme. In the first year I initially wanted to be a turner as I liked working on the manual lathes, but then I enjoyed the technical side of milling more when I moved onto that. Since progressing into the main factory I've been in Inspection, the Fitting Shop and I also did some welding. I'm currently in the Lab Section which usues a range of skills. It's great having an opportunity to try so many different things. |

Ben - Fitting SectionI was at technical college and they recommended me to apply to work at Silverson.

The company didn't have a formal apprenticeship scheme at the time so I continued my NVQ studies while working here. I started in the stores and despatch and quickly moved to the Lab Section where I was trained in assembly of Silverson’s smaller mixers. Having completed my studies and apprenticeship I’m now working in the main fitting shop. I like working with my hands and this is very much a hands on job. The work varies from day to day and I enjoy the challenge that brings. |